Stencil Cleaning System

Machine Over View

- Simple to use machine with Android based interactive user interface

- Versatile machine with closed loop systems for cleaning, rinsing (optional) and drying

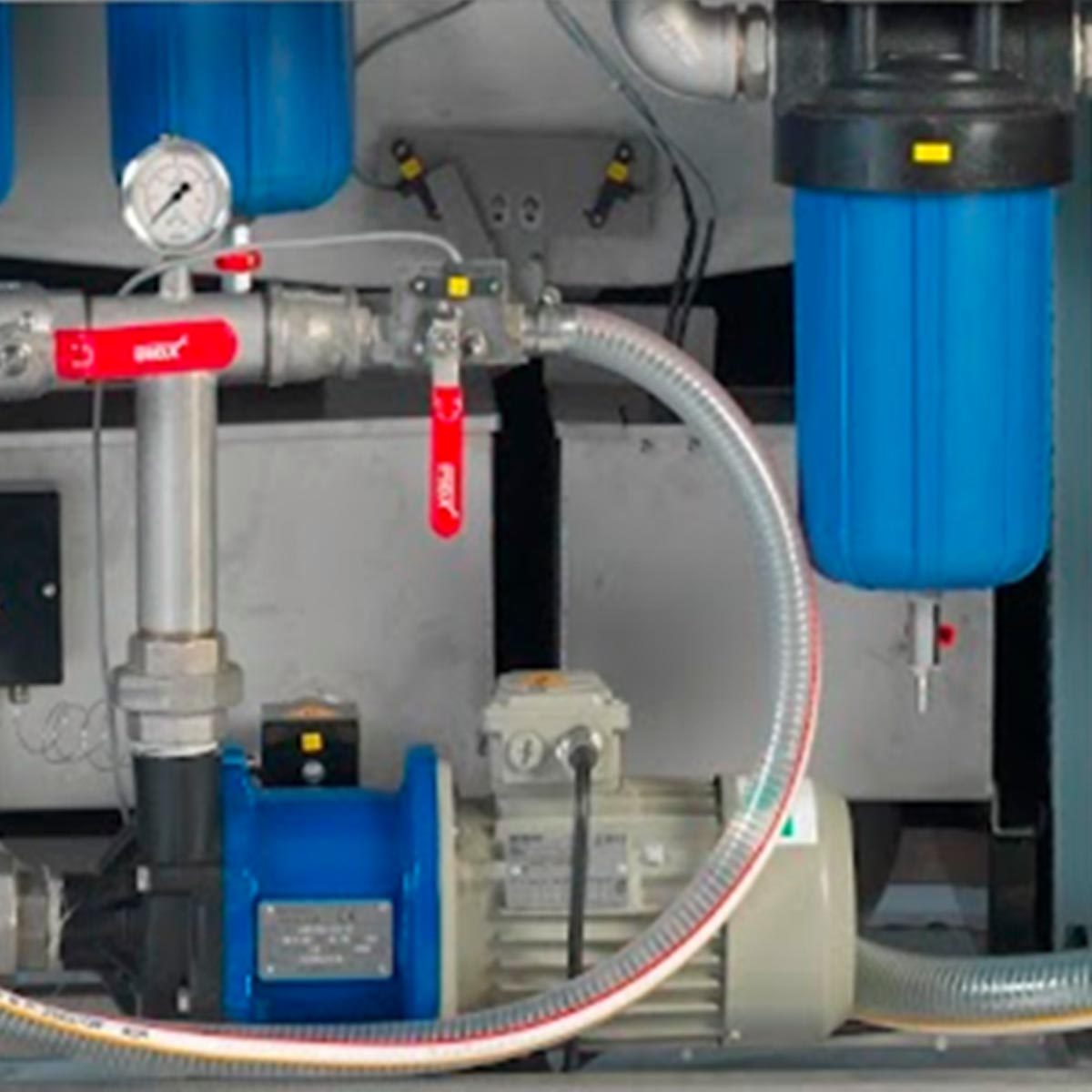

- Separate spray pumps and filtration systems

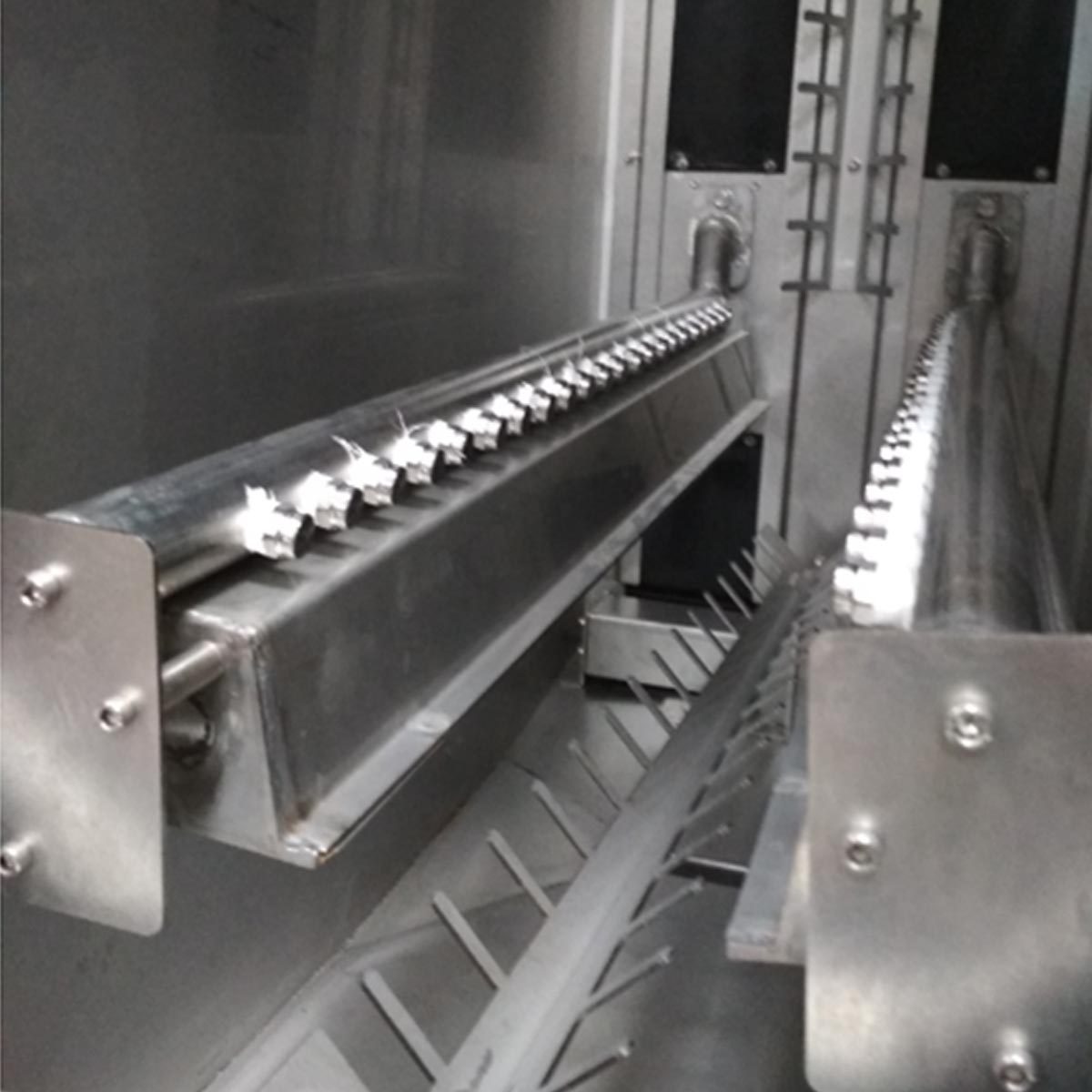

- Vertical elevator mechanism mounted with synchronous Spray Arms and Air Knives

- Linear fluid delivery technology

- Low pressure spray nozzles with <1 bar for cleaning of sensitive screens and stencils

- Vertical elevator mechanism with adjustable stroke

- Simple cleaning, rinsing and drying process with user programmed parameters

Machine Over View

Two models available

- Single Tank (ST) - Single tank for cleaning liquid

- Double tank (DT) - Dual tanks for separate cleaning and rinsing liquids

Ideal for cleaning adhesive or solder paste stencils

Typical applications for double tank machine

- Metal Stencil Cleaning

- Pump Print Stencil Cleaning

- Misprint Cleaning

- PCBA Defluxing

- Squeegee Cleaning

- Screen Cleaning

- Maintenance Part Cleaning

To learn more about the EPS SC-740 Stencil Cleaning System and its highlights, simply download our datasheet below.

Contact our Cleaning specialist

Our sales and technical team are on hand to support any questions you may have.

Swipe for more

| Specification | Single Tank (ST) | Double Tank (DT) |

| Length (L-R) | 950mm | 950mm |

| Depth (F-B) | 1250mm | 1250mm |

| Height | 1850mm | 1850mm |

| Frame Dimension | 740 x 740mm (29 x 29”) max. | 740 x 740mm (29 x 29”) max. |

| Controller | 10” Touchscreen with PLC | 10” Touchscreen with PLC |

| Dry Weight | Approx. 350Kg | Approx. 360Kg |

| Voltage Supply | 400V 3-Ø (3NPE) 50Hz | 400V 3-Ø (3NPE) 50Hz |

Swipe for more

| Cleaning Unit | ||

| Wash Tank Volume | 65 Litres | 65 Litres |

| Pump | Magnetically Coupled Centrifugal | Magnetically Coupled Centrifugal |

| Filters | 20 Micron & 5 Micron 10”LD | 20 Micron & 5 Micron 10”LD |

| Heater | 1 x 3kW Max. 60°C | 1 x 3kW Max. 60°C |

| Nozzle Pressure | Approx. 0.9 Bar | Approx. 0.9 Bar |

| Typical Cycle Time | 3 to 6 Minutes | 3 to 6 Minutes |