Stencil Printer

The ITW EAE Momentum II HiE is designed and built to be a no-nonsense production machine. Cost-efficient and featuring a modest footprint, it grows with the user; innovative patented features can be added on or retrofitted as needed as the user’s throughput demands grow. Numerous patents protect the Momentum, which incorporates tried and true systems and features from other successful MPM printers that were designed prior to Momentum II (and still in use today). Momentum’s alignment repeatability is ±11 microns @ 6 sigma, Cpk ≥2. Its 6 sigma capability is designed in and independently verified. Wet print accuracy is ±17 microns @ 6 sigma, Cpk ≥2. Tighter performance tolerances mean higher repeatability with fewer defects.

The ITW EAE MPM Momentum HiE (for High Efficiency) is a single-rail printer with servo motors, rather than stepper motors, driving the vision system’s X, Y, and Z axes. Faster than steppers, servos drive the vision gantry at higher speed and thus increase throughput and cut cycle time, making the Hi-E an efficient high volume printer.

To learn more about the Momentum HiE II and its highlights, simply download our datasheet below.

Contact our Surface Mount specialist

Our sales and technical team are on hand to support any questions you may have.

Swipe for more

| Higher Speed, Higher Throughput Machine vision inspection occupies a significant amount of time in each print cycle. Most of that involves the physical motion of system components. By speeding component motion, we shave away cycle time, increase efficiency, and accumulate savings. |

| Proven Momentum Series Accuracy and Performance Alignment repeatability of ±11 microns @ 6 sigma, Cpk ≥2 and wet Print accuracy of 20µm@6σ, Cpk ≥ 2, with 6σ capability designed in and independently verified. The MPM Momentum series printers are fast, precise, and highly reliable, with performance unmatched by any other printer in their class. |

| Benchmark User Interface Easy to learn and use for the average operator, MPM’s Benchmark software is powerful yet intuitive, and facilitates rapid setup, assists with operational tasks, and makes changeover quick and easy. The software has been upgraded to Windows 10 and new production tools and new Quickstart programming to make it even easier to use. |

| AccuCheck Print Capability Verification AccuCheck Print Capability Verification allows the printer to measure its own print capability. Users can verify the machine’s capability at any time or continuously on their own products. AccuCheck measures the actual print deposit position versus the target pad to determine a measured print offset. It is an inexpensive, reliable method of obtaining machine quality and process capability information to ensure repeatable results and optimum printing performance. |

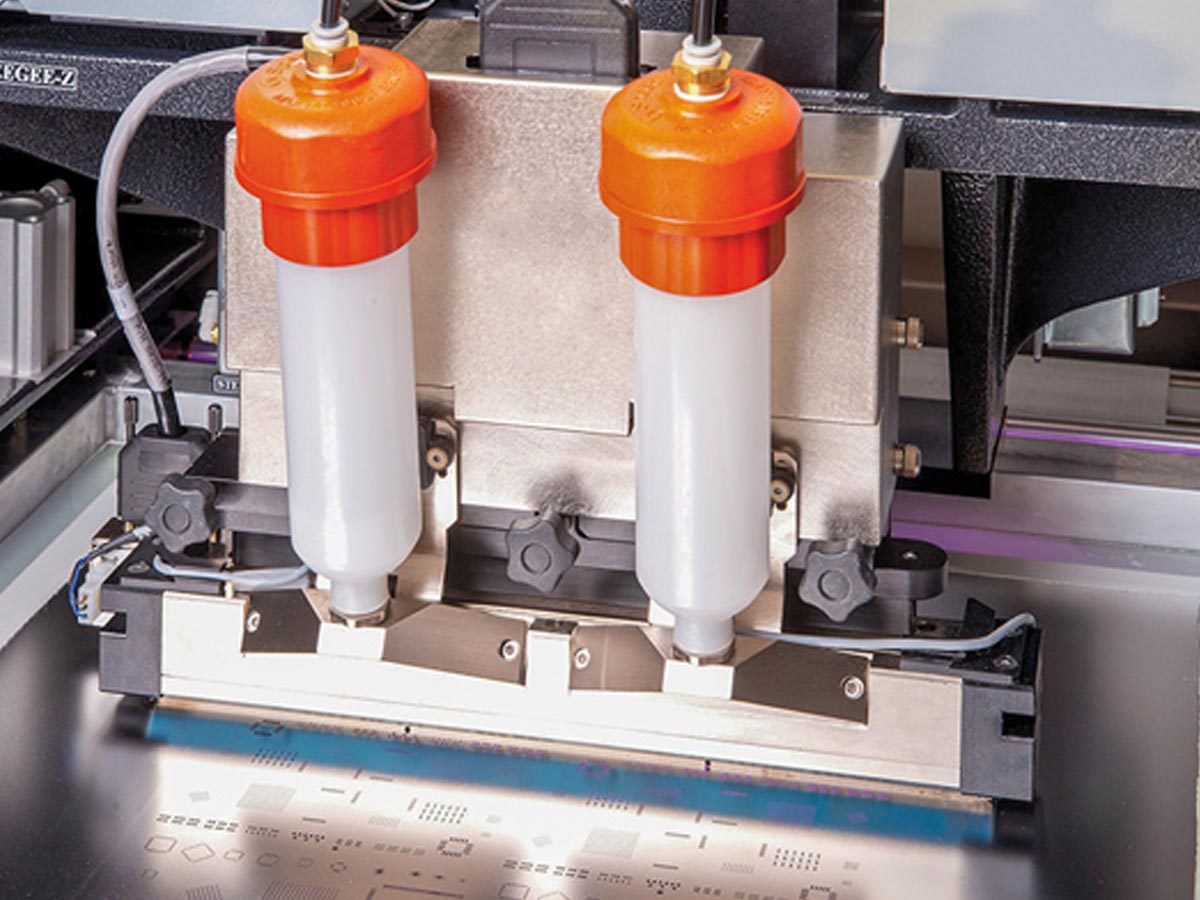

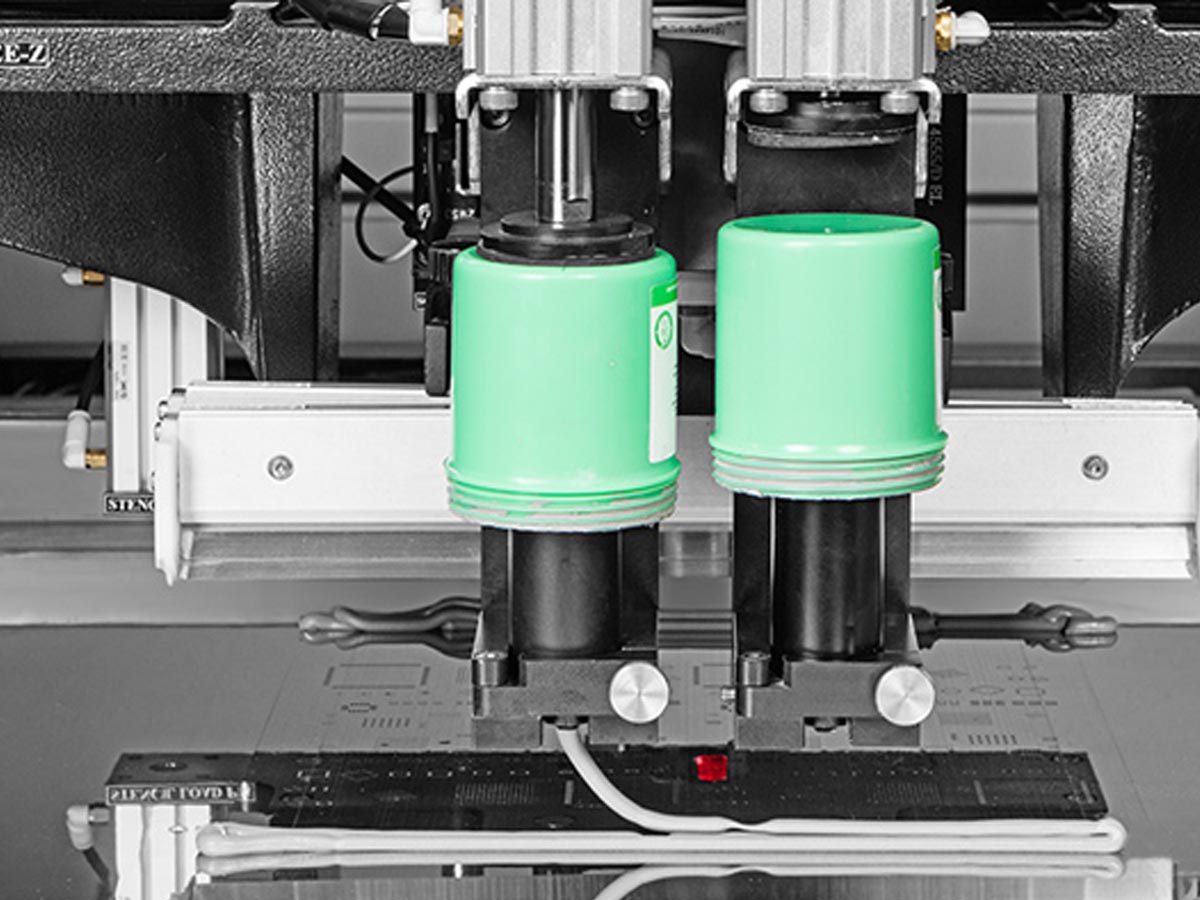

| Automatic Paste Dispensing System Dispense for standard cartridges or choose the new patent-pending jar dispenser. Paste is released in precise, measured amounts across the stencil in a clean, uniform bead. Deposition volumes, frequency and placement are user programmable. Download the Automatic Paste Dispenser brochure |

| Automatic Pin Placement Automatic Pin Placement is MPM’s patented tooling solution that uses the vision gantry to precisely place and remove tooling pins. The carousel holds 48 pins to match and support the largest board size. A standard grid for single sided boards or an exact pin placement for double sided boards can be developed. |

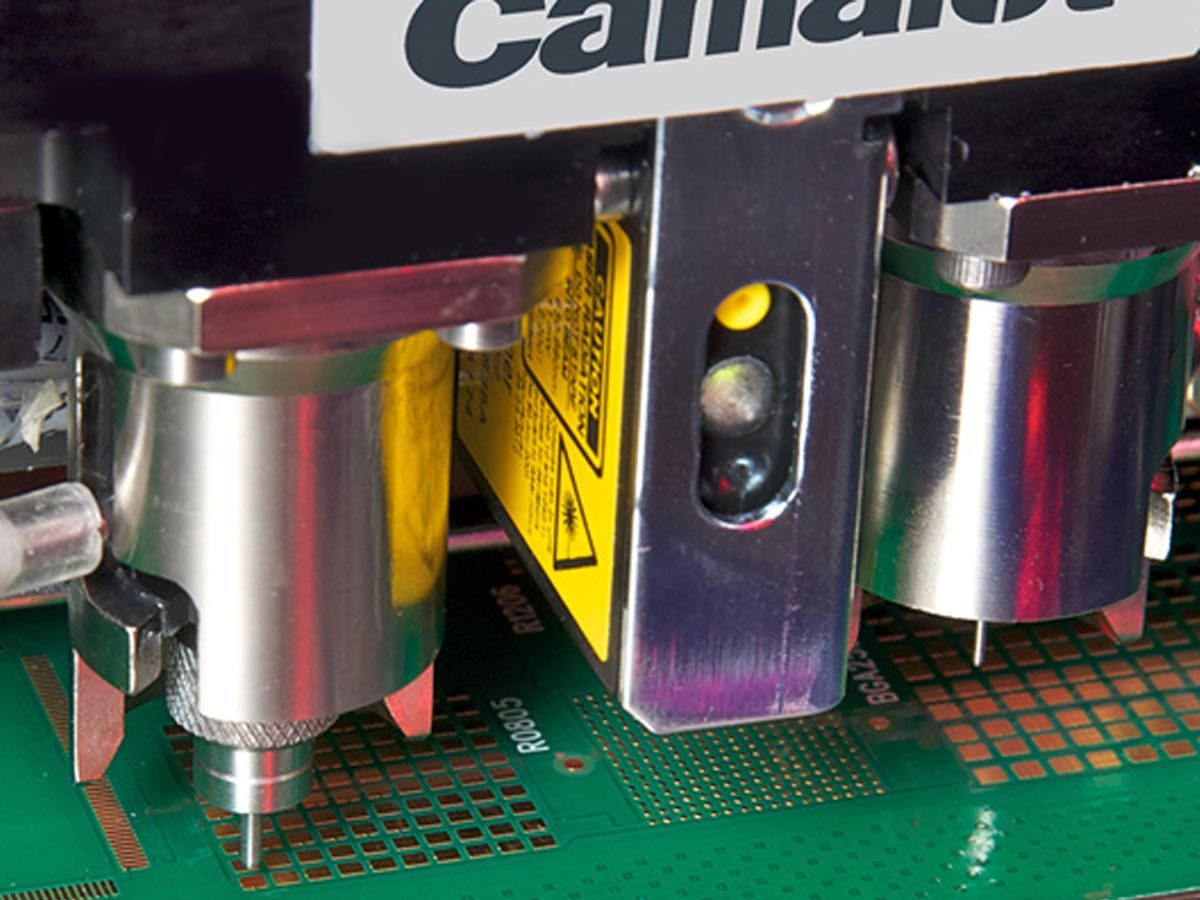

| Camalot Inside Integrated Dispensing System Only ITW EAE, with industry-leading core competencies in printer AND dispenser technologies, can bring both together to the customer’s advantage. Camalot Inside consists of two dispense pumps integrated into one printing machine. Camalot Inside provides ultimate flexibility, allowing the dispensing of two different materials, or the same material (doubling dispense throughput speed) with two needle sizes to easily administer multiple dot sizes. Download the Camalot Inside brochure |

| EdgeLoc II Board Clamping System The EdgeLoc system uses a side snugging technique that removes the need for top clamps which interfere with the PCB to stencil contact. The result is optimal gasketing and more volumetrically consistent edge-to-edge prints. Choose the robust EdgeLoc II with side only clamping or EdgeLoc+ which can change between edge and top clamping; Download the EdgeLoc brochure |

| EnclosedFlow Print Head The EnclosedFlow print head offers significant process and cost advantages over printing with metal squeegee blades, particularly for fine-feature printing. Solder paste is held within an enclosed chamber, and is directly pressurized during the print stroke to provide uniform and complete aperture filling for the full range of aperture sizes and fill types. The EnclosedFlow print head delivers superior volume/yield on fine pitch pads. Print fine pitch features such as 01005s and 0.3 mm pitch CSPs with up to 50% greater volume and 25% lower deviation that squeegee blades. The EnclosedFlow print head ensures optimal aperture filling for fine pitch devices and crisp uniform printing with less waste. Download the EnclosedFlow Print Head brochure |

| MPM Vision System & Inspection The MPM’s patented printe rbased Vision and Inspection system is a cost-effective way to verify print and paste deposit results. It is flexible enough to handle the complete range of today’s most challenging components. This system measures the amount of paste covering the target pad and compares it with the required coverage. 2D inspection is integrated directly into the stencil printer to provide an immediate source of data. |

| OpenApps Architecture MPM’s OpenApps is an open architecture source code which provides the capability of developing custom interfaces in support of Industry 4.0 initiatives and communication with Manufacturing Execution Systems (MES). ITW EAE is the first SMT company to offer open software architecture. |

| Paste Height Monitor The Paste Height Monitor is designed to prevent defects caused y inadequate volumes of paste on the stencil. It combines advanced software and sensor technology to accurately monitor the paste bead for volume consistency. Upper and lower limit roll-height monitoring eliminates insufficient or excess paste volumes. It is a non-contact solution that can automatically add more paste to the stencil as it is needed. Download the Paste Height Monitor brochure |

| Paste Temperature Monitor Temperature monitoring ensures proper paste viscosity to avoid bridging and voiding. MPM patent- pending paste temperature monitor allows paste to be measured in the cartridge or on the stencil. Download the Paste Temperature Monitor brochure |

| PrinTrack The PrinTrack feature adds traceability, data harvesting, and reporting to your printing process. With PrinTrack, you always have an easy access to a comprehensive history, detailing:

A flexible web reporting interface can be user-configured to produce traceability reports. Download the PinTrack brochure |

| Quick Release Squeegee New quick release squeegee blades make changing blades quick and easy with no tools required. It takes less than 30 seconds to change the blade. |

| RapidClean Stencil Cleaner The RapidClean stencil cleaner is a high-speed stencil cleaning solution that improves cleaning performance and cuts cycle time. The RapidClean stencil cleaner provides precise wet/dry wipe transition and exceptional cleaning results with its paper over plenum design, venture vacuum, and patented roller solvent bar delivery system. Download the RapidClean brochure |

| RapidView Inspection Built on our patented optics technology, RapidView system delivers high-speed 2D inspection with device-level SPC reporting. RapidView inspection is up to three and half times faster than our standard system, can increase Field of View (FOE) 4x, and can work in conjunction with our GerberEZ Teach system. |

| SPI Print Optimiser The SPI print optimiser communicates with the external Solder Paste Inspection (SPI) system to continuously monitor and auto-correct X, Y, and Theta registration ‘on the fly’ to stay on target and prevent print defects. |

| Support Pin Placement Pin location can now be verified with bottom side image whether placing pins automatically or manually. |

Swipe for more

| Maximum Board Size (X x Y) | 609.6 mm x 508 mm (24” x 20”) A dedicated workholder is required for boards with an X size greater than 20” |

| Minimum Board Size (X x Y) | 50.8 mm x 50.8 mm (2” x 2”) |

| Maximum Board Weight | 4.5 kg (10 lbs) |

| Maximum Print Area (X x Y) | 609.6 mm x 508 mm (24” x 20") |