Stencil Printer

The ITW EAE Momentum II 100 delivers performance that one would expect to find only in higher-priced printing machines. This hard-working printer utilizes the robust, reliable Momentum

series platform that has been proven to be at the top of its class in facilities around the world, yet its value pricing makes the Momentum II 100 an incredible bargain.

Cost-efficient and featuring a modest footprint, it grows with the user; innovative patented features can be added on or retrofitted as needed as the user’s throughput demands grow.

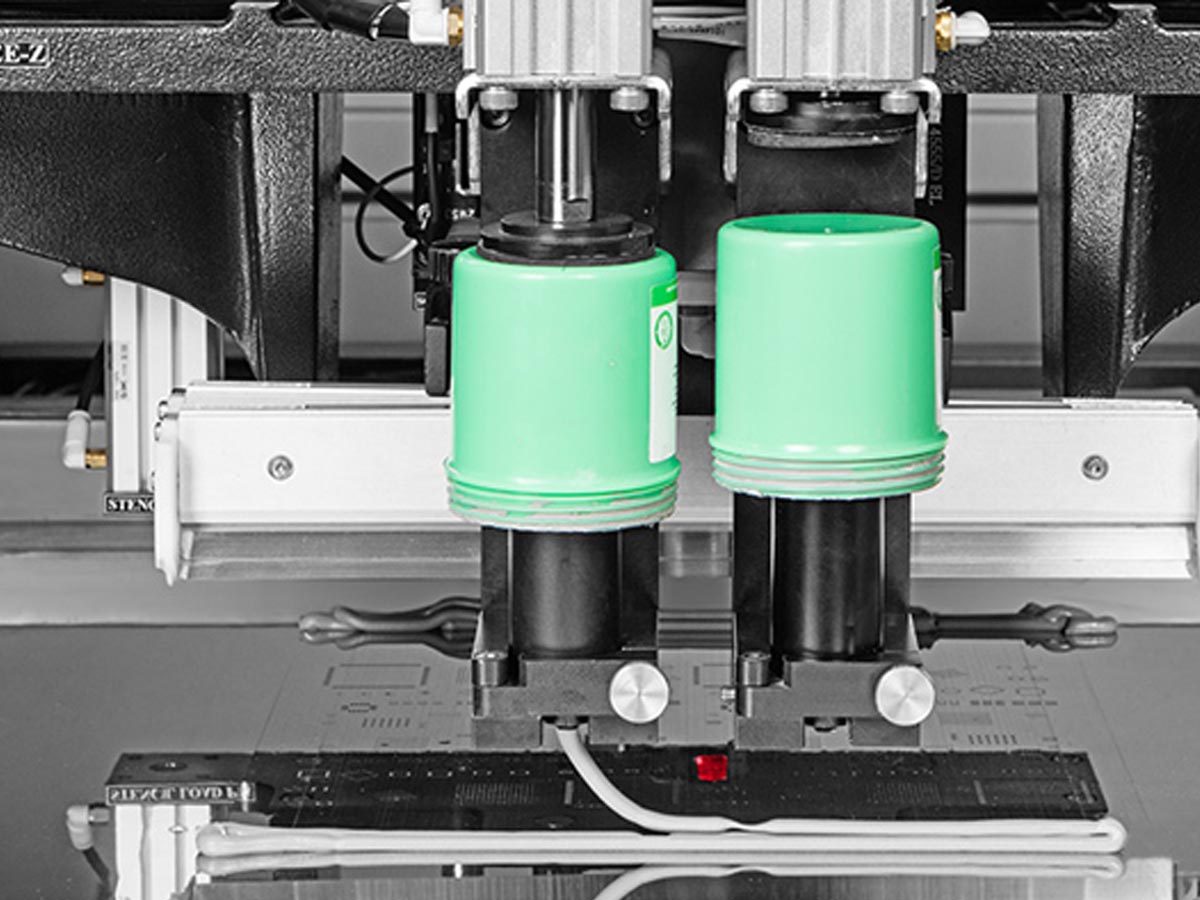

The Momentum II 100 can accommodate a wide range of PCB sizes from 609.6mm x 508 mm (24” x 20”) down to is 50.8 mm x 50.8 mm (2” x 2”). Its wet print accuracy is ±20 microns @ 6 Sigma, Cpk ≥2.0. Tighter performance tolerances mean higher repeatability with fewer defects. Plus, a cycle time of 11 seconds ensures moderate to high throughput for its size. Programmable and closed-loop squeegee systems ensure accurate and repeatable squeegee force with every print stroke; the system auto-compensates for squeegee deflection, and no force adjustment is needed for squeegee variations. For basic, repeatable printing quality with high yields and true affordability, the Momentum II 100 has no equal.

ITW EAE MPM Momentum II 100 New Features

- Newly designed cover set with larger window and wider access inside the printer.

- Quick release squeegee for faster changeover.

- Adjustable stencil shelf for flexibility handling board varieties.

- New jar paste dispenser for increased productivity.

- Solder paste roll height and paste temperature monitoring for yield improvement and traceability.

- Upgraded Benchmark GUI with customizable production page and Quickstart program.

- Windows 10 operating system.

To learn more about the Momentum II 100 and its highlights, simply download our datasheet below.

Contact our Surface Mount Specialist

Our sales and technical team are on hand to support any questions you may have.

Swipe for more

| Proven Momentum II Series Accuracy and Performance Alignment repeatability of ±11 microns @ 6 sigma, Cpk ≥2 and wet Print accuracy of 20µm@6σ, Cpk ≥ 2, with 6σ capability designed in and independently verified. The Momentum II series stencil printers are fast, precise, and highly reliable, with performance unmatched by any other printer in their class. |

| More Throughput in Less Space The Momentum II 100 is a space-saving 200 mm shorter than the standard Momentum II stencil printer platform. Configured for Back-to-Back (BTB) processing, for example, two individual printers back to back in a manufacturing line enables dual-lane processing with the combined output of two machines, but in the line length of one. |

| Total Front-Side Access The Momentum II 100 is designed for total front-side accessibility for simplified service to the electrical system, access to the solvent reservoir, and more. Without the need for rear access space, adjacent BTB machines help you make the most of every inch of your floor space. |

| Faster ROI and Low Cost of Ownership Accurate and repeatable performance delivers quality products with fewer defects. The reasonable cost of ownership for the Momentum II 100 printer ensures you'll see a faster ROI, and higher profitability going forward. |

| Benchmark User Interface Easy to learn and use for the average operator, MPM’s Benchmark software is powerful yet intuitive, and facilitates rapid setup, assists with operational tasks, and makes changeover quick and easy. The software has been upgraded to Windows 10 and new production tools and new Quickstart programming to make it even easier to use. |

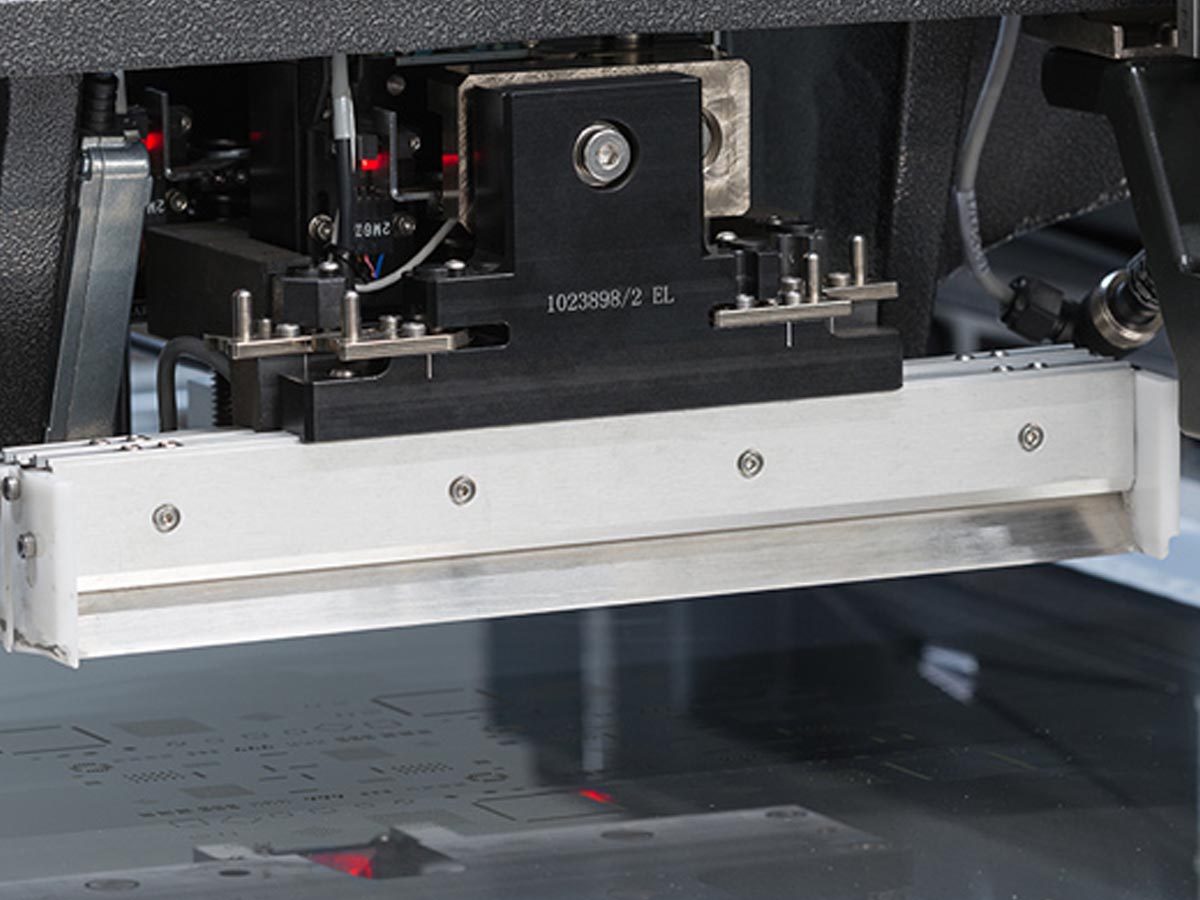

| AccuCheck Print Capability Verification AccuCheck Print Capability Verification allows the printer to measure its own print capability. Users can verify the machine’s capability at any time or continuously on their own products. AccuCheck measures the actual print deposit position versus the target pad to determine a measured print offset. It is an inexpensive, reliable method of obtaining machine quality and process capability information to ensure repeatable results and optimum printing performance. |

| Adjustable Stencil Shelf Provides the flexibility to handle all stencil sizes with a simple adjustment of the shelf. The robust design provides better stability on all stencil sizes. |

| Automatic Paste Dispensing System Dispense for standard cartridges or choose the new patent-pending jar dispenser. Paste is released in precise, measured amounts across the stencil in a clean, uniform bead. Deposition volumes, frequency and placement are user programmable. Download Automatic Paste Dispensing System Brochure |

| BridgeVision and StencilVision System BridgeVision is a patented method of analyzing bridge defects on circuit boards in the post-print inspection process. This innovative system utilizes texture-based image acquisition algorithms and a digital camera system with telecentric lenses to support the accurate identification of paste deposit defects. StencilVision utilizes texturebased technology to check the underside of a stencil for solder paste contamination. Wiper operation can be driven by the results obtained. |

| MPM Vision System & Inspection MPM’s patented printe rbased Vision and Inspection system is a cost-effective way to verify print and paste deposit results. It is flexible enough to handle the complete range of today’s most challenging components. This system measures the amount of paste covering the target pad and compares it with the required coverage. 2D inspection is integrated directly into the stencil printer to provide an immediate source of data. |

| OpenApps Architecture MPM’s OpenApps is an open architecture source code which provides the capability of developing custom interfaces in support of Industry 4.0 initiatives and communication with Manufacturing Execution Systems (MES). ITW EAE is the first SMT company to offer open software architecture. |

| Paste Height Monitor The Paste Height Monitor is designed to prevent defects caused y inadequate volumes of paste on the stencil. It combines advanced software and sensor technology to accurately monitor the paste bead for volume consistency. Upper and lower limit roll-height monitoring eliminates insufficient or excess paste volumes. It is a non-contact solution that can automatically add more paste to the stencil as it is needed. |

| Paste Temperature Monitor Temperature monitoring ensures proper paste viscosity to avoid bridging and voiding. MPM patent- pending paste temperature monitor allows paste to be measured in the cartridge or on the stencil.Upper and lower limit roll-height monitoring eliminates insufficient or excess paste volumes. It is a non-contact solution that can automatically add more paste to the stencil as it is needed. Download Paste Height Monitor Brochure |

| PrinTrack PrinTrack™ adds traceability, data harvesting and reporting to your printing process. It can seamlessly integrate with other equipment and elements in the manufacturing cycle, such as MES and ERP, and can be expanded factory-wide. Download PrinTrack Brochure |

| Quick Release Squeegee New quick release squeegee blades make changing blades quick and easy with no tools required. It takes less than 30 seconds to change the blade. |

| RapidClean Stencil Cleaner RapidClean is a high-speed under-stencil cleaning system offered on MPM Momentum series printers. RapidClean is the fastest stencil cleaning solution available. Download RapidClean Brochure |

| SPI Print Optimizer SPI Print Optimizer brings your Solder Paste Inspection (SPI) machine into communication with your MPM printer through a specially-developed common interface. When the SPI machine ‘sees’ X, Y and theta offset problems on a just-printed PCB, it analyzes the data virtually instantly and gives the printer instructions to correct those offsets, automatically, and ‘on the fly’. Download SPI Print Optimiser Brochure |

Swipe for more

| Maximum Board Size (X x Y) | 609.6 mm x 508 mm (24” x 20”) A dedicated workholder is required for boards with an X size greater than 20” |

| Minimum Board Size (X x Y) | 50.8 mm x 50.8 mm (2” x 2”) |

| Maximum Board Weight | 4.5 kg (10 lbs) |

| Maximum Print Area (X x Y) | 609.6 mm x 508 mm (24” x 20") |

| Print Speed | 0.635 mm/s - 304.8 mm/s (0.025 in/s - 12 in/s) |

| Print Force | 0 to 22.7 kg (0 lb to 50 lbs) |