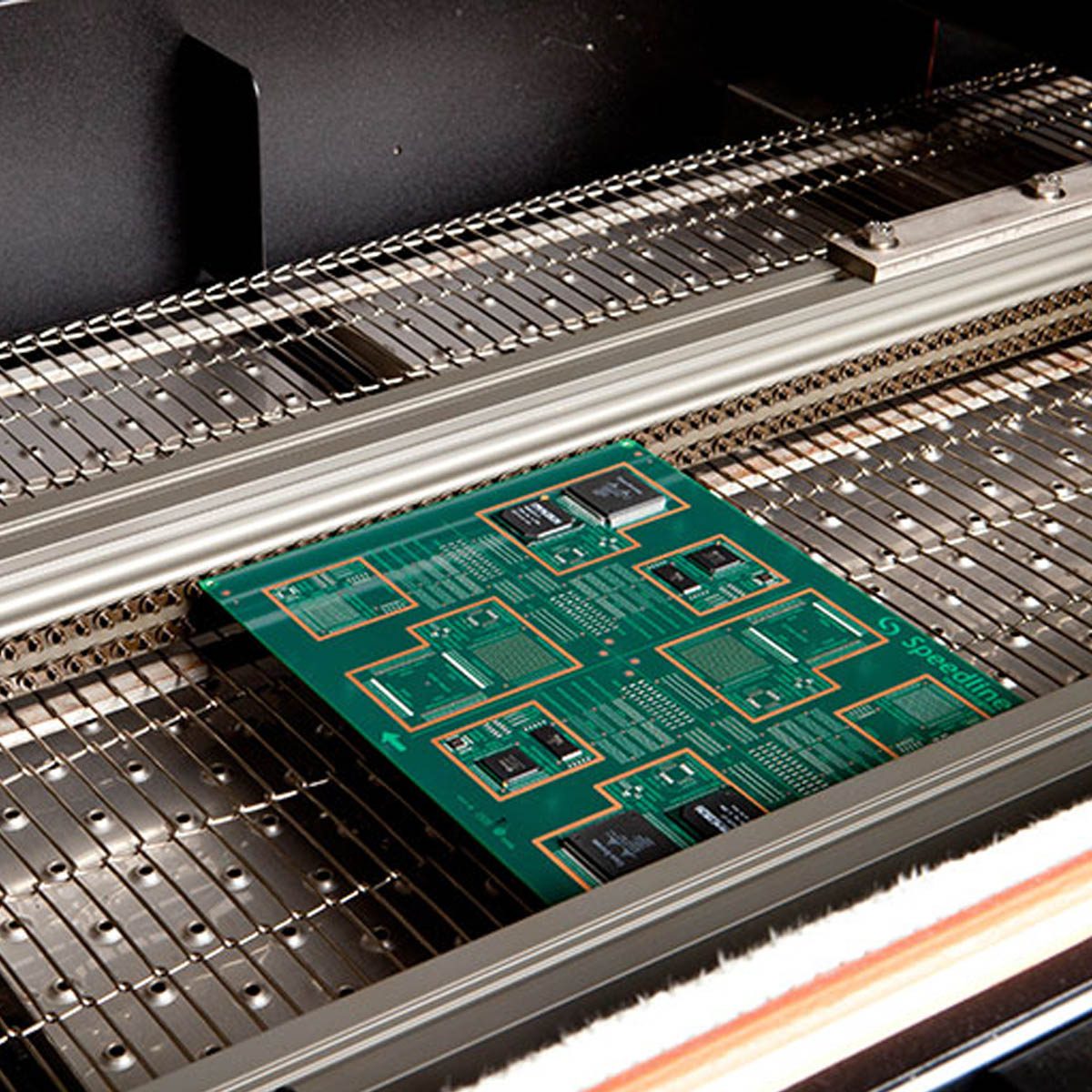

Electrovert OmniES 5 Zone Reflow System

ITW EAE Electrovert OmniES 5 Zone reflow soldering system is designed to deliver maximum thermal performance combined with process capability and control. The OmniES platform offers a combination of industry-proven technologies in an easy to use, reliable and efficient mass reflow system for high-end production requirements. From lead-free to hybrid processing, the OmniES 5-zone oven delivers superb yields. The OmniES sets the standard in innovative technologies that save on the lowest power and nitrogen consumption rates.

Proven Performance, World Class Results

The patented IsoThermal™ chamber technology is what differentiates Electrovert ovens from others. In a reflow oven, the consistent thermal capability and control within the heated length is what matters most rather than the number of zones. The OmniES 5 uses a single IsoThermal chamber design producing a hybrid approach to consistent thermal capability and control that outperforms competitive low cost alternatives. The OmniES produces ΔT’s less than ±3°C. The OmniES is proven to require significantly less power than other ovens in the market.

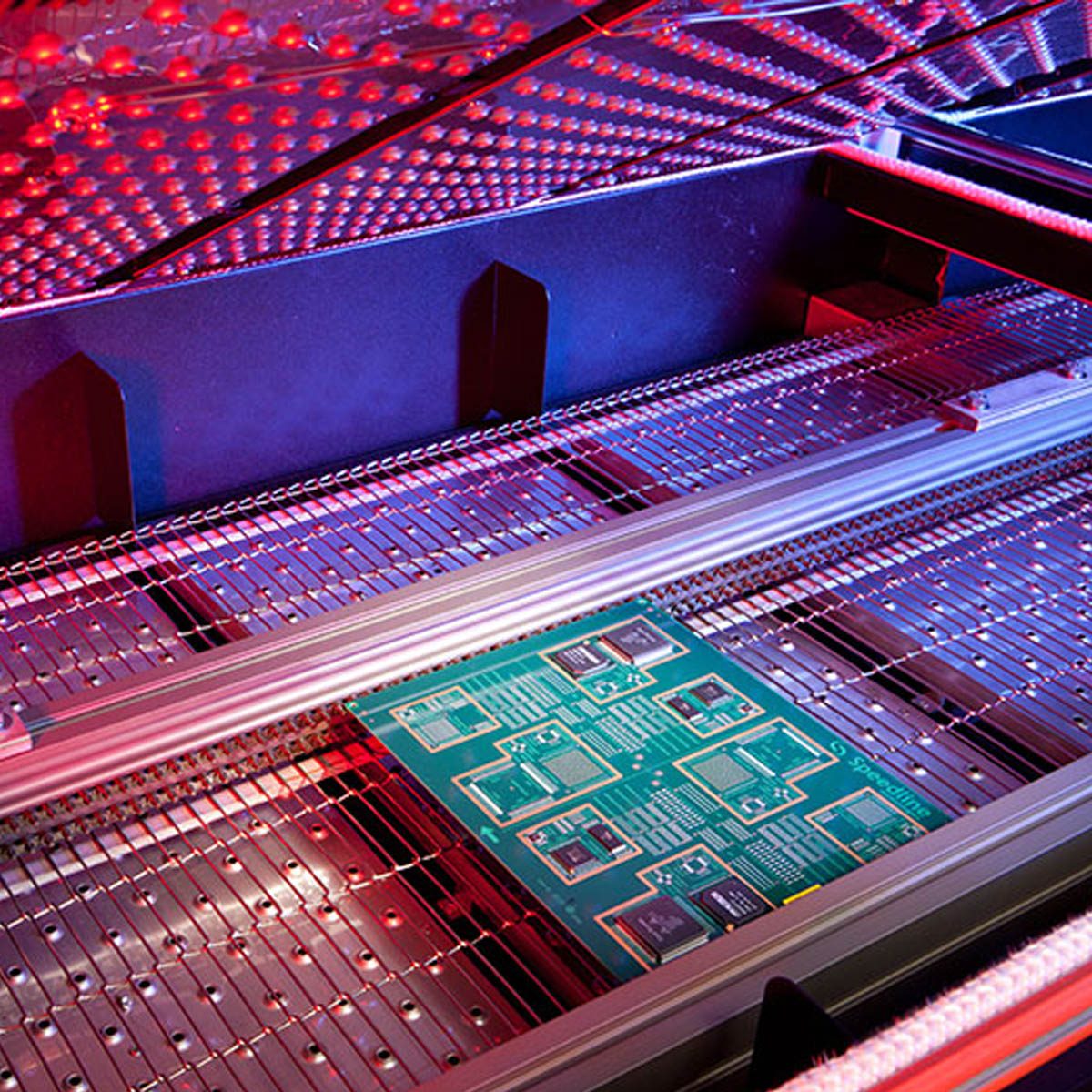

Advanced Heating Chamber Technology

The OmniMax and OmniES incorporate the patented IsoThermal™ Chamber Technology (ICT). This is an advanced, efficient heating chamber design that provides maximum thermal performance. Electrovert’s innovative approach to thermal transfer delivers highly efficient heat transfer throughout the entire process and product. Consistent thermal performance of the ICT promotes excellent zone separation, minimizes cross board ΔT’s and allows for better control of time above liquidus.

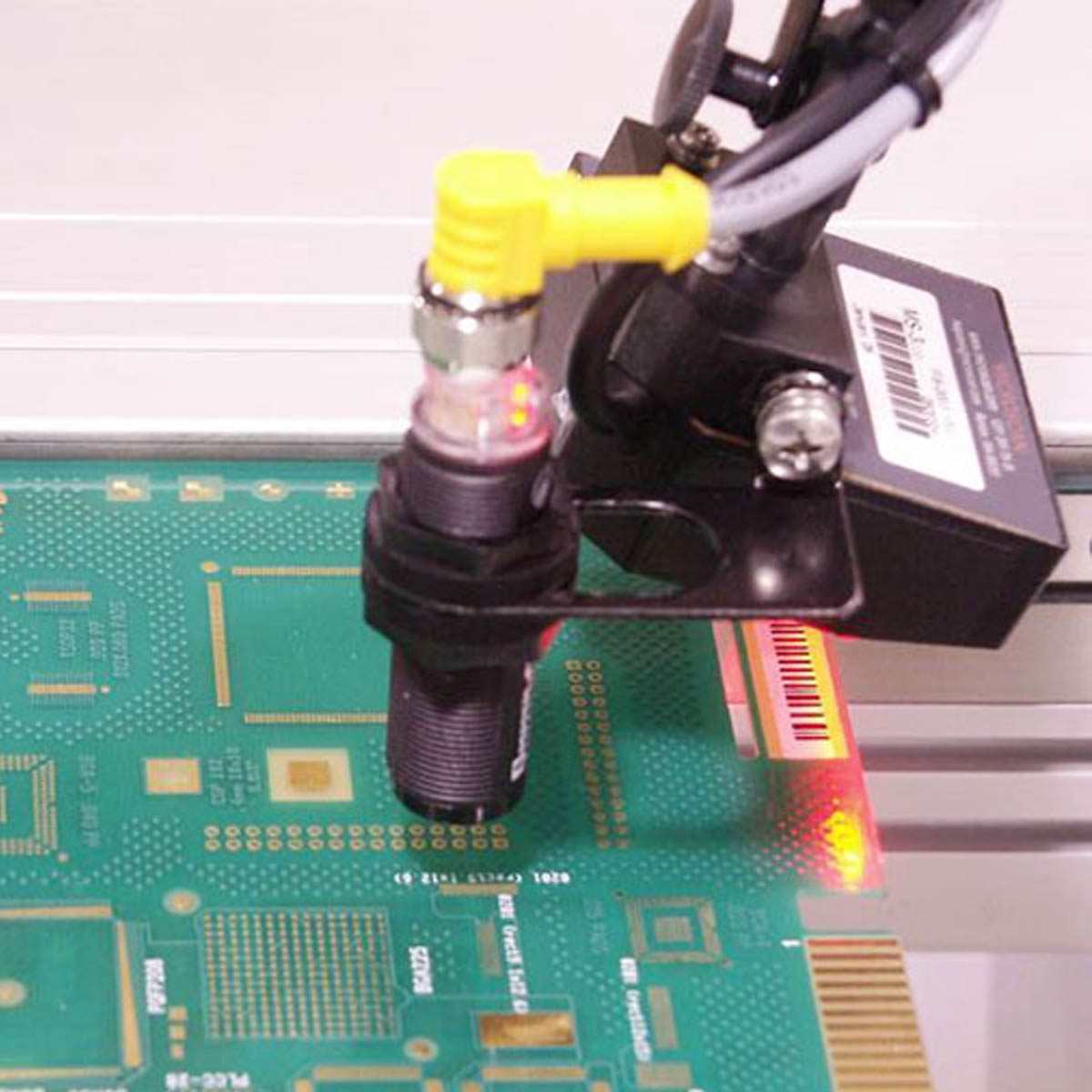

Innovative Cooling

The patented cooling module in OmniMax/ES series is designed to provide process flexibility, to meet the cooling slope requirements of thermally-challenging board assemblies, and to reduce the opportunity for flux dripping in the process area. The air flow dynamics within the cooling zones are efficiently controlled for a balanced environment that can reduce nitrogen consumption up to 20-25%. The design includes a patented dripless cooling module that significantly reduces the potential for flux dripping in the cooling area. Excellent separation between the heating and cooling areas produces a tight control of time-above-liquidus.

To learn more about the OmniES 5 and its highlights, simply download our datasheet below.

Contact our Surface Mount Specialist

Our sales and technical team are on hand to support any questions you may have.