WaveRIDER coupon improves accuracy and repeatability

Establishing the wave soldering process can be challenging. And, with many soldering specialists leaving the electronics industry, the science of wave soldering is becoming a lost art and expertise is often hard to find.

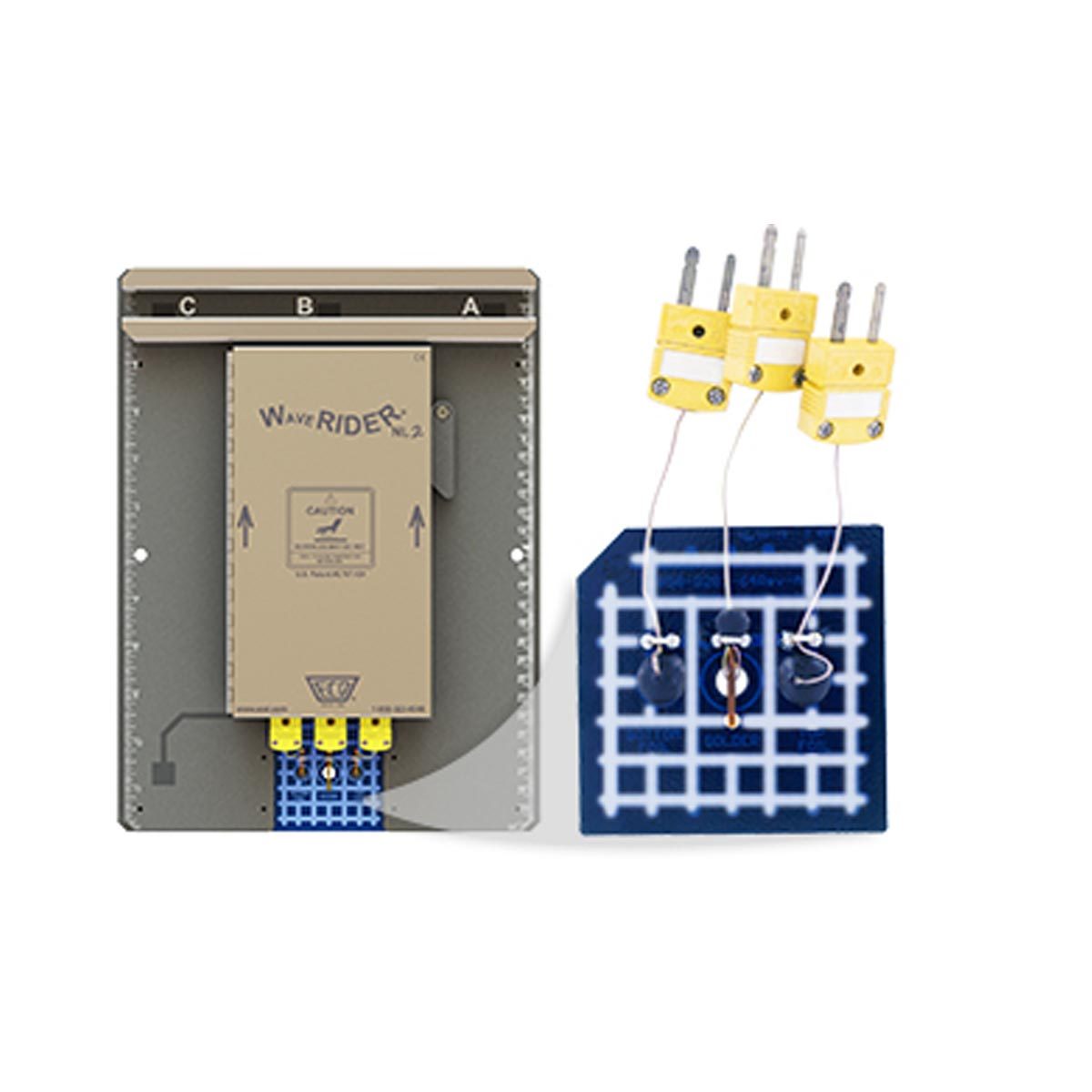

The ECD WaveRIDER® NL 2 solves this dilemma. As the easiest and most effective tool for wave soldering process verification, WaveRIDER offers process verification measurement to help fill the expertise void. Used in combination with the SuperM.O.L.E.® Gold or SuperM.O.L.E.® Gold 2 thermal profiler, this robust tool measures and monitors preheat temperatures and slopes, conveyor speed, wave contact times and parallelism.

Ready to learn more about WaveRIDER? Download the Expert's Guide to Wave Soldering begin analyzing your wave soldering process and then call ECD to learn more about WaveRIDER.

WaveRIDER® NL 2, like all ECD products, is backed by our award-winning service and support. Learn more about ECD’s top-rated service. Contact our support team today.

Features

New WaveRIDER coupon improves accuracy and repeatability!

In our continuing commitment to bring our customers the best products possible, we have recently made a design improvement to our WaveRIDER coupon. We have added an anchor to our solder thermocouple which fixes it at a 2mm depth. This should provide better repeatability, and additionally give a better representative solder temperatures. Existing users can upgrade to the new style coupons, but will need to expect a shift in their data (old style coupons will remain available to support existing customer needs should they choose to maintain their existing data sets.).

- Measurement Parameters include:

- Dwell (contact) time

- Contact length

- Conveyor Speed

- Wave Parallelism

- Preheat Ramp (slope)

- Delta T at Wave

- Solder Temperature

- Top & Bottom side Board Temperature

- Immersion Depth

- Settable Upper and Lower Measurement Spec limits

- SPC control charts

- One piece pallet and thermal barrier

Benefits

- Allows control of machine stability with a reliable test fixture instead of a Golden Board

- Fine-tuning of the Wave Solder machine raises productivity

- Quantifies machine measurements for informed control

- Helps reduce rework

- Eliminates guessing and tightens maintenance protocol

- Provides data to operators for a Go/No-Go indication of machine readiness

- Maximizes yields and improves profitability

- Reassures customers that through-hole soldering is in control

- Saves time and effort as machine can be profiled without attaching thermocouples

- Enables pre-emptive machine adjustments

- Trackable, historic electronic data collection more reliable than glass plates

To learn more about the WaveRIDER NL 2 and its highlights, simply download our datasheet below.

Contact our specialist

Our sales and technical team are on hand to support any questions you may have.