Printer

Overview

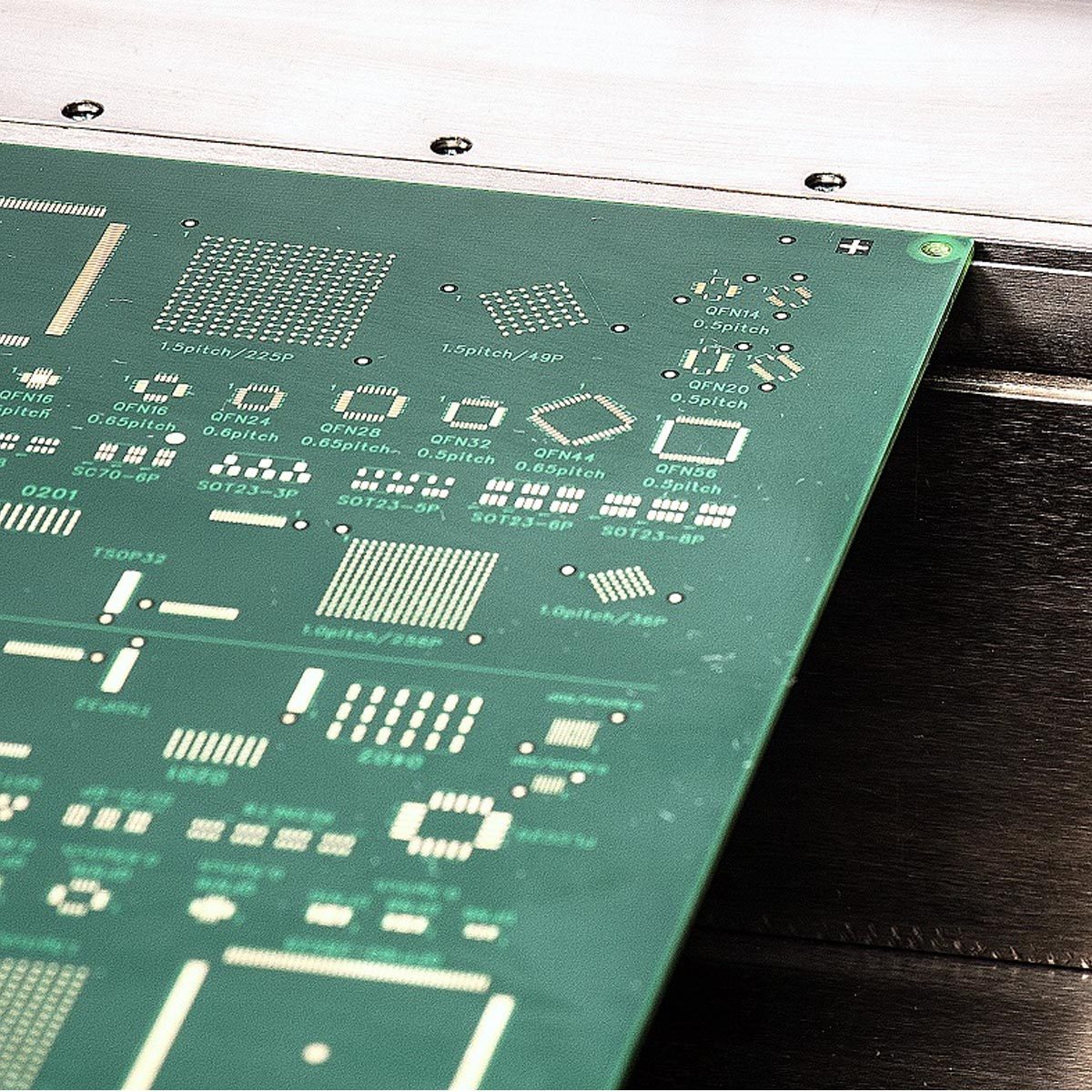

The MPM Edison Printer is ideally suited for the burgeoning Automotive and Smart device manufacturing markets. It is the industries’ most accurate printer with +/- 15μ @ 6σ wet print repeatability. Total throughput is lightning fast due in part to the highly-efficient, patentend parallel processing of the stencil shuttle system, stencil wiping, paste dispensing and vision alignment system.

Benefits and Features

Unparalleled Throughput and Speed

The MPM Edison Printer delivers an unheard-of higher throughput than competitive printers –15 seconds total throughput, including stencil wipe cycle. That’s due in part to an all new highly-efficient parallel processing stencil shuttle system, wiper, vision gantry, and other cycle time reduction and innovations so that Edison delivers double the throughput of best-in-class printers worldwide.

Incomparable Wet Print Accuracy

For accuracy, Edison has no equal. Edison has built-in +/- 8 micron alignment, and +/- 15 micron wet print repeatability (≥2 Cpk @ 6σ) proven through 3rd party Print Capability Analysis (PCA) testing. This represents a 25% improvement in wet print accuracy over current best-in-class printing machines.

New Intueri Graphical User Interface

Intueri is a simple, intuitive operator interface with a flexible, wide array of configuration variables. It is combined with Open Apps for maximum capability and connectivity. Intueri is a portal to Industry 4.0 concepts.

Unprecedented Access and Back to Back (BTB) Configurable

Edison’s recessed front design provides unprecedented access to tooling and makes servicing easy without reaching, bending, or fatigue. Edison can also be configured ‘Back to Back’ for a flexible dual lane solution without adding line length.

Enhanced Technology

High Speed Vision Alignment with Ultra-slim Camera

Overall gantry thickness is only 39mm featuring ‘on the fly’ ‘POE’ (Power Over Ethernet) camera; A single CCD split field provides precision simultaneous up-down image acquisition; FOV 9.7 x 6.0 mm.

Advanced Print Head Option

Single axis closed-loop pressure control for dual squeegee eliminates front-to-back variation; a single high precision load cell provides squeegee force, and a unique algorithm calibrates out non-linearity, maintaining the set pressure across the entire board surface.

Ultra-fast, High Efficiency Wiping System

The super-size 65m roll lets you make 10,000 prints between change-outs, for example, with a 5 print frequency, for less down time; the system also features a unique Contamination Control Design.

Innovative EdgeLoc+ Board Clamping

MPM's EdgeLoc™+ board clamping system takes board handling to the next level by having the capability to change between edge and top clamping simply through software.

EdgeLoc uses software-controlled pressure for optimal board holding force, automatically adapts to the programmed board thickness. Thin boards can be held with the top clamps while simultaneously adding light edge clamping force for maximum flexibility.

SPI Print Optimizer

The SPI print optimizer communicates with the external Solder Paste Inspection (SPI) system to continuously monitor and auto-correct X, Y, and Theta registration ‘on the fly’ to stay on target and prevent print defects.

Open Apps

MPM’s Open Apps feature is an open architecture source code which provides customers and third parties the capability of developing custom interfaces in support of Industry 4.0 initiatives and Manufacturing Execution Systems (MES).

To learn more about the Edison Printer and its highlights, simply download our datasheet below.

Contact our Surface Mount Specialist

Our sales and technical team are on hand to support any questions you may have.

Swipe for more

| Minimum Board Size (X x Y) | 50 mm x 50 mm (1.97” x 1.97”) |

| Maximum Board Weight | 4.5 kg (10 lbs) |

| Board Edge Clearance | 3.0 mm (0.118") |

| Underside Clearance | 12.7 mm (0.5") standard Configurable for 25.4 mm (1.0”) |

| Maximum Print Area (X x Y) | 450 mm x 350 mm (17.72 x 13.78") |

| Print Speed | 305 mm/sec (12.0"/sec) |