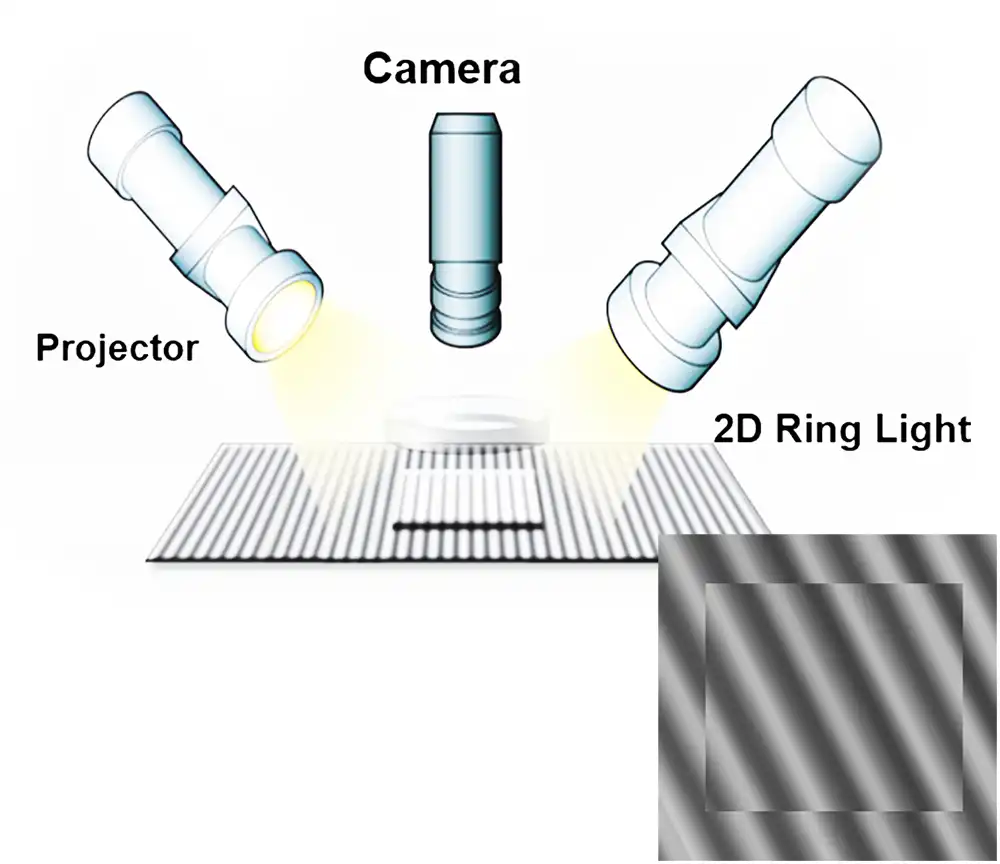

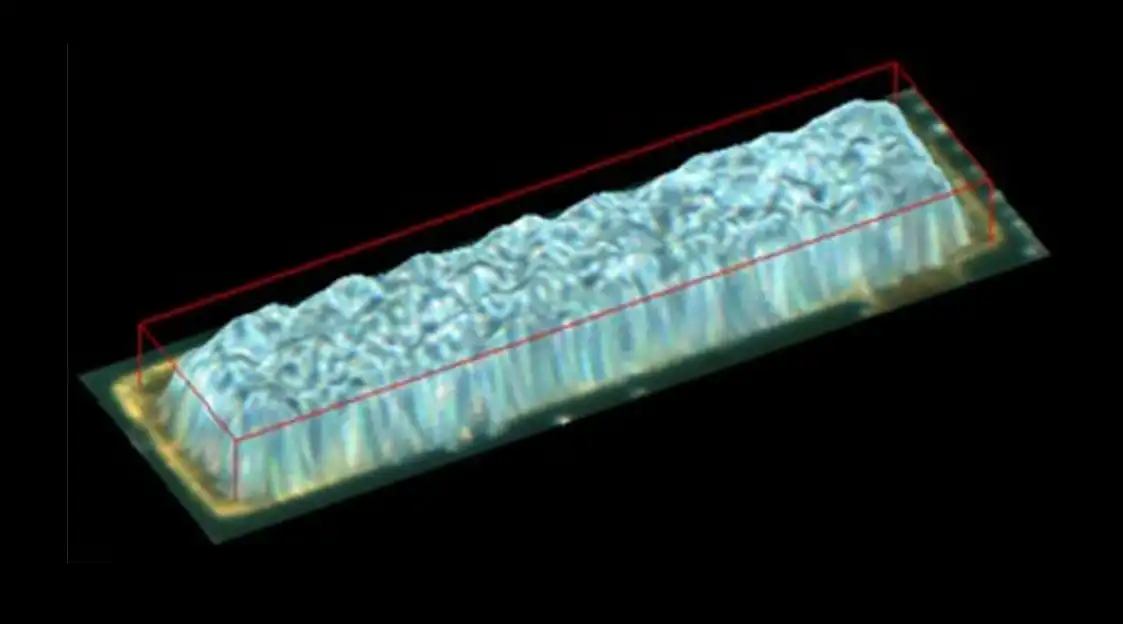

The VP9000 3D-SPI uses highly accurate and repeatable 3D imaging to perform complete PCB solder paste analysis. Potential PCB war-page is calculated at each inspection point and automatically compensated for prioritisation to analysis. The combination of features achieve ultra-precise volume measurements with an high accuracy.

OMRON | 3D-SPI System

VP9000

World’s Newest 3D-SPI System

Is this system right for you?

Let our expert team guide you in choosing the perfect system for your needs.

Please complete all fields below to download the datasheet.

The Omron VP9000 uses highly accurate and repeatable 3D imaging to perform complete PCB solder paste analysis. Potential PCB war-page is calculated at each inspection point and automatically compensated for prioritisation to analysis. The combination of features achieve ultra-precise volume measurements with an high accuracy.

Simple, user-friendly offline programming software creates inspection programs in minutes. Unique features like automatic component registration and self-adjusting lighting make program creation simple and streamlined. ePM software programming compatibility can further improve the programming process.

The VP9000 touch-screen, colour interface and fluid 2D/3D modelling provides operators immediate, interactive inspection result feedback. Inspection results can be reviewed while the next PCB is being inspected to improve productivity. The advanced data analysis software provides comprehensive quality data for continuous manufacturing process improvement and trend monitoring.

The Omron VP9000 can feed inspection result data back to the screen-printer, making necessary print adjustments in real-time to eliminate the continuation of defects during production.

Our team of specialists offer knowledge and expertise in your imaging process.

Features

- High-Speed 100% 3D Solder Paste Inspection

- Highly Accurate Solder Paste Volume Measurement (within 2%)

- Multiple Resolution Options and 3-Mode Zoom (down to 5µm)

- Two Available Machine Sizes to Handle PCBs Ranging from 250mm x 330mm to 460mm x 510mm

- User-Friendly Software and Integrated, Touch-Screen Interface

- Simple Program Creation from GERBER and/or Mount Data (compatible with ePM)

- Full Offline Program Generation

- Real-Time Process Monitoring

- Data Analysis and Quality Control Software Tools (compatible with Omron Q-Up Navi software)

- Glue and Foreign Material Inspection.

Full 3D Data Processing and realisation of Industrial 4.0 Smart Factory Solution.

Omron Q-upNavi: Combine SPI, AOI and AXI Result Data Together for True Root-Cause Analysis.

Omron Q-upAuto: Total Quality Control Across the Entire Production Line.

VP9000 is the latest 3D-SPI technology on the market, suitable for tomorrows production environments.

Absolute precision with OMRON's cutting-edge inspection systems.

OMRON Inspection Systems are industry-leading solutions designed to ensure the highest standards of quality and precision in electronics manufacturing. These systems use advanced automated optical inspection (AOI) technology, alongside cutting-edge image processing and machine learning algorithms, to detect defects and inconsistencies with exceptional accuracy.

Designed for modern production lines, OMRON’s inspection systems are capable of identifying a wide range of defects, including soldering issues, misaligned components, and surface irregularities. They offer real-time monitoring and feedback, helping manufacturers improve production efficiency and reduce costly errors.

Known for their adaptability, OMRON’s solutions support a variety of production environments, from high-mix, low-volume operations to large-scale manufacturing. With intuitive user interfaces, high-speed inspections, and seamless integration into existing workflows, OMRON Inspection Systems provide manufacturers with the tools required to maintain strict quality control and drive continuous improvement.