The Omron VT-S1080 is the world’s most advanced 3D AOI system, designed for the high-quality manufacturing market. New technologies to overcome the shortfall in production yields traditionally caused by shadow, reflection and cycle-time to realise unmanned inspection process in combination with labour-saving maintenance, using predictive maintenance.

OMRON | 3D AOI System

VT-S1080

Designed for the high-quality manufacturing market.

Is this system right for you?

Let our expert team guide you in choosing the perfect system for your needs.

Our team of specialists offer knowledge and expertise in your imaging process.

Remove takt time bottlenecks and reduce operator related steps and man-hour related inspections.

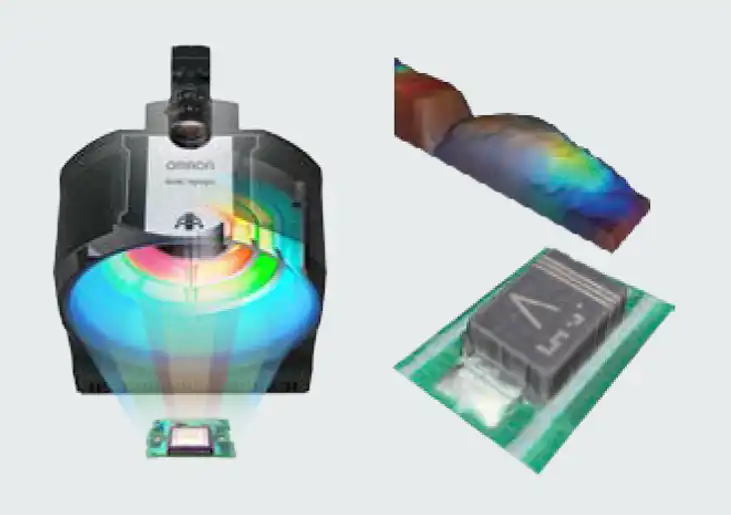

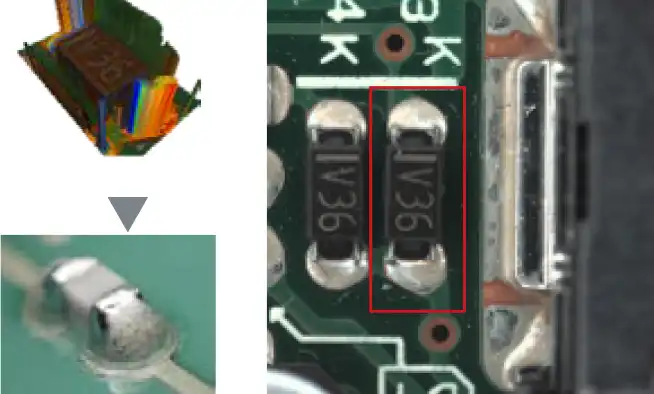

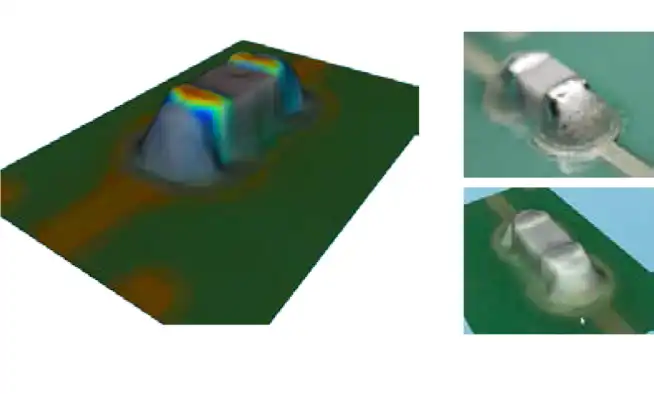

High-precision solder shape reconstruction helps achieve zero defect products

The combination of Omron’s own patented technologies achieves highly robust and reliable inspection performance.

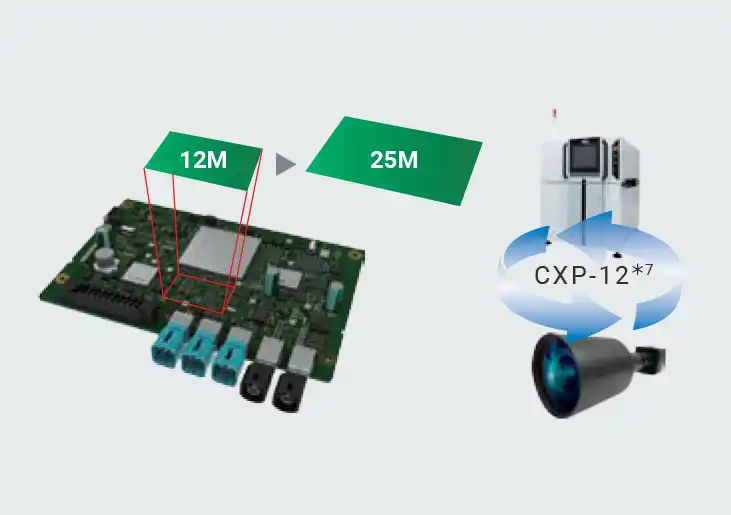

High-speed, high-quality images

- Equipped with an OMRON in-house camera optimised for inspection.

- High-definition images with low noise and strong contrast acquired and inspected at high speed.

- The inspection speed is about 150%* 8 faster than the conventional one

Phase shift+ MPS

- Equipped with a proprietary design projector.

- Automatic control of multiple fringe patterns and light intensity realises optimal inspection.

- The effect of secondary reflective is also minimised by use of MPS technology.

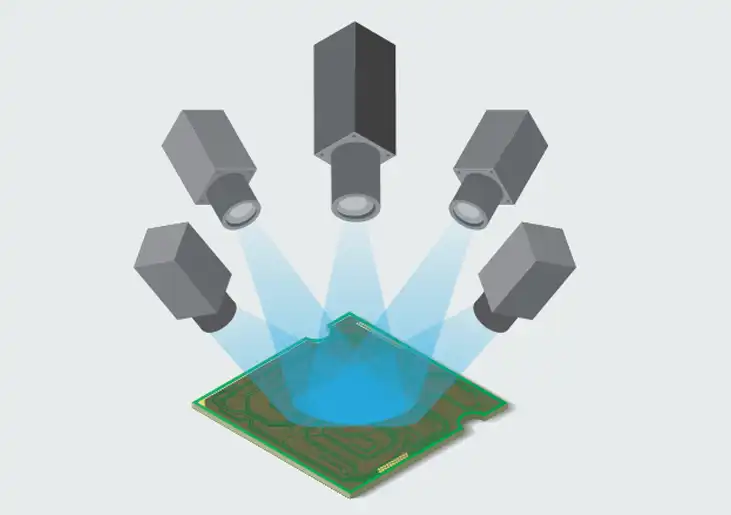

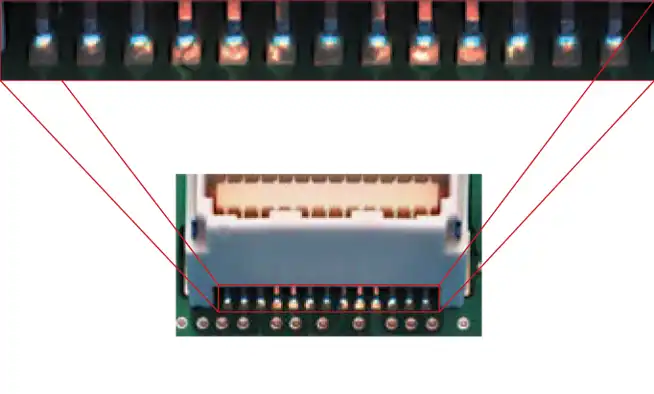

Direction lighting + White lighting

- Equipped with a technique to Irradiate multidirectional RGB lights.

- More high-precision inspection accomplished by capturing variety of shape information even complex fillet shapes.

- Applied white lighting allows accurate detection and reading of component printing.

Higher accuracy with AI model generated from huge number of images.

| Omron VT-1080 | |

| Outer dimentions | 1180(W) x 1450(D) x 1500(H)mm (excluding tower lamp and monitor) |

| Weight | Approx. 1240Kg |

| Power supply | 200 to 240 V AC (Single phase); Voltage fluctuation range ±10% 50/60Hz |

| Rated power | 2.0 kVA (Maximum current 10 A) |

| Line height | 900±20mm |

| Air supply | Not required |

| Operating temperature range | 10~35℃ |

| Operating humidity range | 35 to 80% RH (Non-condensing) |

| Camera | Direct 25Mpix / Oblique 5Mpix |

| Resolution | Direct 12.5μm / Oblique 10μm |

| FOV | Direct 52.5 x 52.5mm / Oblique 25.9 x 19.4mm |

Absolute precision with OMRON's cutting-edge inspection systems.

OMRON Inspection Systems are industry-leading solutions designed to ensure the highest standards of quality and precision in electronics manufacturing. These systems use advanced automated optical inspection (AOI) technology, alongside cutting-edge image processing and machine learning algorithms, to detect defects and inconsistencies with exceptional accuracy.

Designed for modern production lines, OMRON’s inspection systems are capable of identifying a wide range of defects, including soldering issues, misaligned components, and surface irregularities. They offer real-time monitoring and feedback, helping manufacturers improve production efficiency and reduce costly errors.

Known for their adaptability, OMRON’s solutions support a variety of production environments, from high-mix, low-volume operations to large-scale manufacturing. With intuitive user interfaces, high-speed inspections, and seamless integration into existing workflows, OMRON Inspection Systems provide manufacturers with the tools required to maintain strict quality control and drive continuous improvement.