Robotas Technologies has 25 years experience of providing solutions for customers whose products have a hand assembled element. We have over 1500 installed systems around the world, for customers including Nokia, Hewlett Packard, Agilent, Intel, Westinghouse, Jabil, Venture and Parker.

SIGMA is a unique and effective aid for product hand assembly. Our customers are typically manufacturers with a wide range of products which are assembled in small / medium batches. Typical product assemblies range from cable harnesses or box build, right up to complex final products.

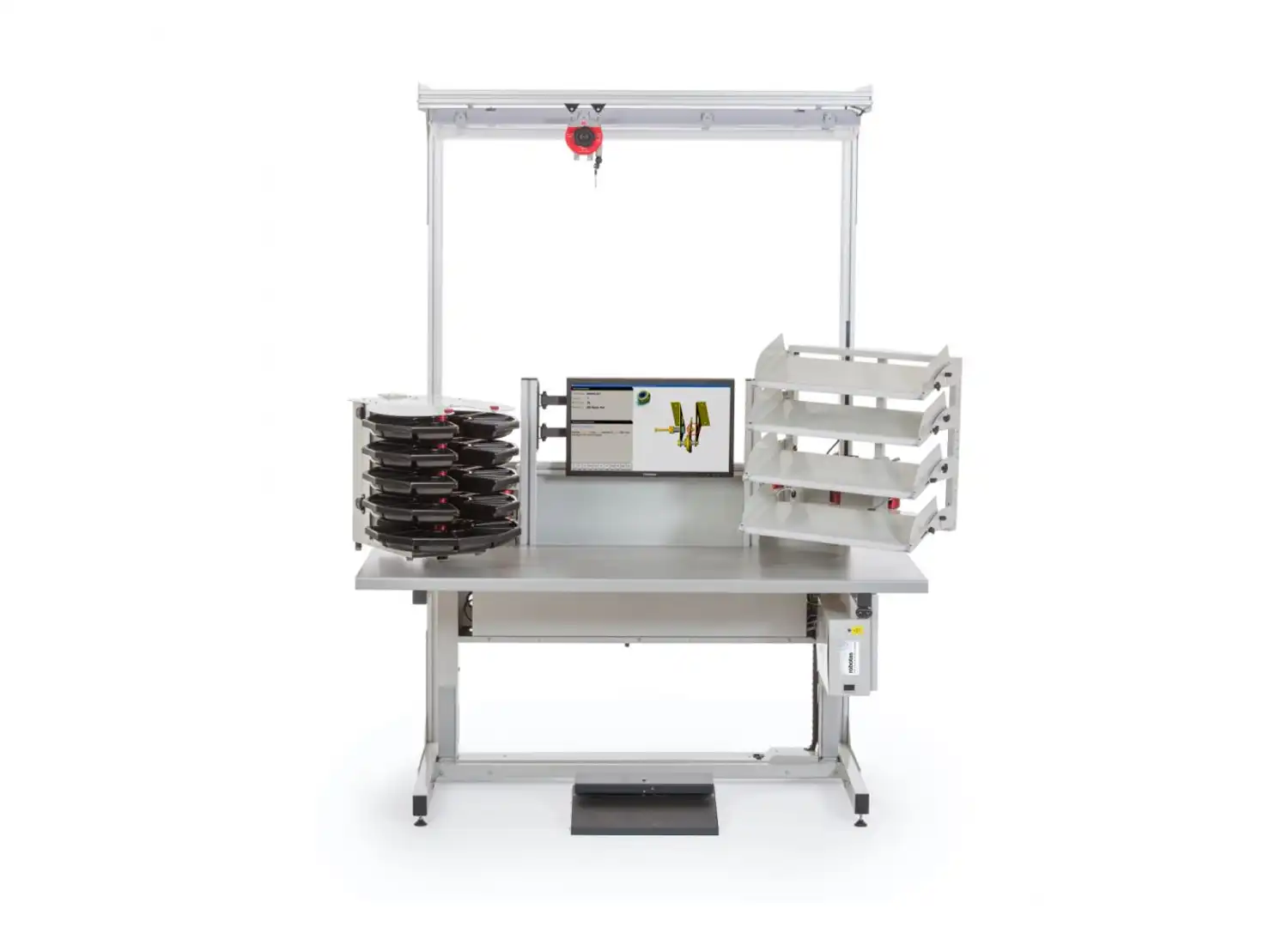

SIGMA gives all possible assistance to the operator. Step by step, SIGMA delivers the right part, the right tool, and the right information to help get the assembly right first time. In the Aerospace, Defence, Medical or indeed any other sector where the highest standards of build quality is crucial, SIGMA can eliminate kitting, speed up product design and introduction, speed up product hand assembly, and significantly reduce error rates.

Build batches of ONE as efficiently as larger batches! Simply select the product to be assembled at the touch of a button, or the scan of a barcode. Working in this way will significantly reduce your set up time, assisting lean manufacturing.

The user friendly operation requires minimal training and allows even inexperienced operators to begin building your products immediately.