Ultimate Performance, BGA Rework Station for small-large PCBs

The PDR IR-E6 Evolution XL rework system is made in the United Kingdom with only the finest components for optimum precision. The PDR IR-E6 Evolution XL is our largest system and one of the best performing BGA Rework Stations worldwide.

The IR-E6 Evolution XL is very high powered with a multi-zone, 3200W PCB preheater and is designed to rework small to large PCB assemblies with upto a 24"/620mm PCB capacity. It is loaded with advanced features delivering many benefits including the highest performance and soldering quality available anywhere, yet it remains simple to set up and use.

High Performance

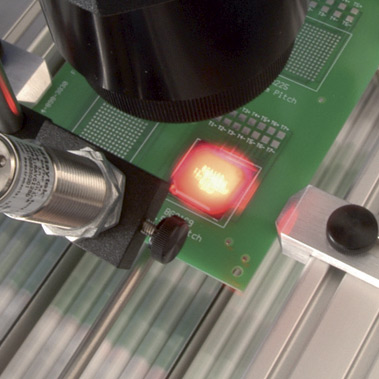

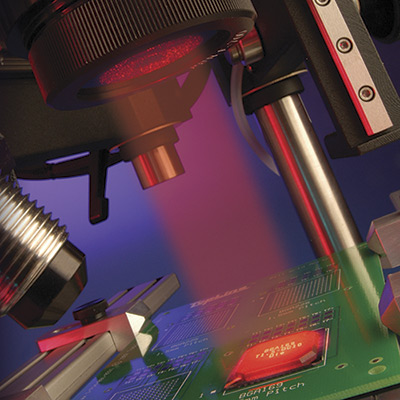

The PDR IR-E6 SMD/BGA rework station, using PDR’s patented Focused IR technology, has been specifically designed to cope with the challenges of repairing today’s PCB assemblies.

The system is tool free, gas free, instantly/precisely controllable, clean, modular, upgradeable and produces 100% yield BGA rework without any complications. It provides the extremely high levels of profiling and process control necessary for the effective rework of even the most advanced packages, including SMDs, BGAs, CSPs, QFNs, Flipchips and is ready for 0201 and lead-free applications.

The IR-E6 is well specified yet can be easily configured to your exact requirements, with a good range of advanced features to choose from, allowing the operator to quickly and safely rework all types of components without overheating the component, adjacents or the PCB. It uses all the proven attributes of PDR’s Focused IR technology, first introduced in 1987 and now used worldwide by over 4500 customers.

Simple BGA Procedure

BGA rework poses the problem of accessing hidden interconnects in a high density environment. Consequently, it requires a system that is able to access the hidden joints without affecting neighbouring components. A system that is safe, gentle, adaptable and, above all, simple to operate. The IR-E6 is such a system. It is so easy to operate that technicians are able to instantly achieve excellent process control for BGA/SMD rework without the complexities and frustrations normally associated with ‘high-end’ rework systems.

Paste - Place - Reflow

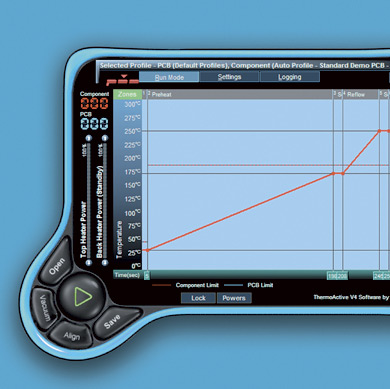

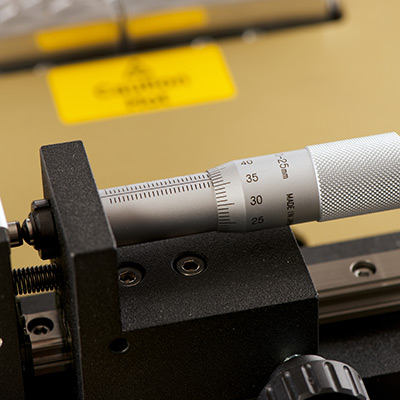

With the aid of excellent mechanics, optics and control, operators can simply pick up the fluxed BGA from the nest, align it, place it onto the PCB’s pads and then reflow with the system’s accurate PC based, closedloop component and PCB temperature control.

To learn more about the IR-E6 Evolution and its highlights, simply download our datasheet below.

Contact our Production Support Specialist

Our sales and technical team are on hand to support any questions you may have.